Product

Track pressing plate

No.:

g001

Category:

Pressing plate

Hotline:+86-315-2020058

EMAIL:jbrs20180709@163.com

Keywords:

Track pressing plate

Detail

- Detail

- Technical advantages

- Operation data

-

- Commodity name: Track pressing plate

- Commodity ID: g001

RailLok ™ There are two types of pressing plates: welding type and bolt type, which can be used for different fixing methods. The product has obtained an invention patent(US8205803B2, EP2173947B1, CN101720371B). Its mechanical performance has passed the test and certification of world-renowned laboratories and has been applied to professional track construction.

RailLok ™ There are two types of pressing plates: welding type and bolt type, which can be used for different fixing methods.

The product has obtained an invention patent(US8205803B2, EP2173947B1, CN101720371B). Its mechanical performance has passed the test and certification of world-renowned laboratories and has been applied to professional track construction.

Welded pressing plate and bolted pressing plate have different dimensions and lateral force resistance levels to adapt to different track shapes and wheel loads. How to select a suitable pressing plate depends not only on these dimensions and mechanical considerations, but also on the installation requirements. Therefore, we suggest that you feed back your needs to us in time, so that we can provide you with the best choice and scheme.

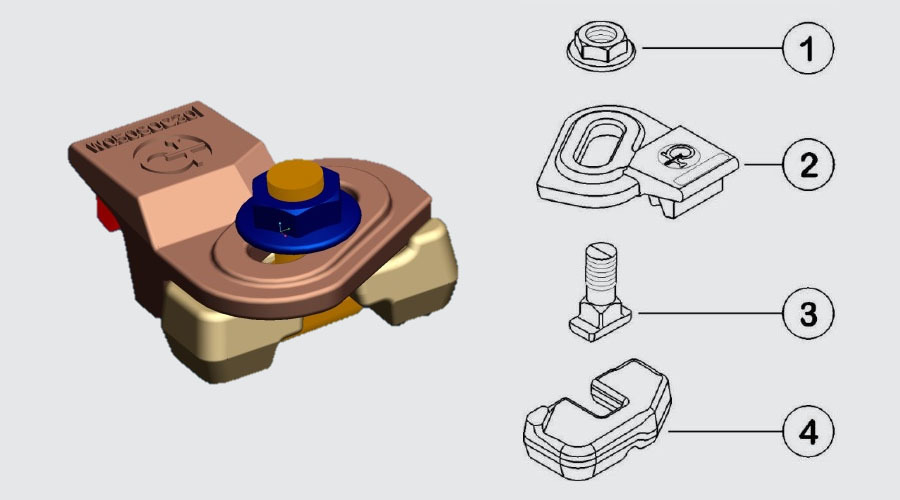

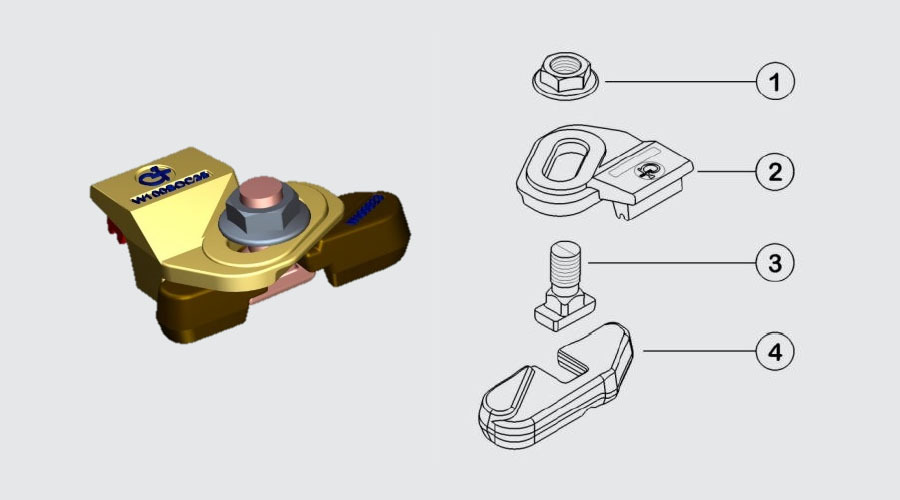

The welded pressing plate is composed of two parts, namely, the lower pressing plate for welding and the upper pressing plate for adjustable parts. The lower platen is welded to the steel plate, and the upper platen is fixed to the lower platen by fastening bolts. The self-locking wedge design of the pressing plate makes the bolts of the pressing plate system always locked. The pressing plate can be adjusted laterally, which can generate self-locking function after being installed in place, and can also further correct the track accuracy during its entire service life. The upper platen uses the rubber nose to apply a downward elastic force to fix the rail. The rubber nose is a synthetic rubber that is pressed on the upper platen with high pressure during the high-temperature vulcanization process. The new "double wedge structure" can provide simple and fast installation. At the same time, the T-bolt allows the use of an electric or starting wrench, which improves the installation efficiency. The lateral adjustment range is 8-20mm, and the maximum lateral force resistance is 65KN-300KN.

Common models of welding type include GANTREX-W10T, GANTREX-W15T, GANTREX-W20T, GANTREX-W25T, GANTREX-W30T.Keywords:- Track pressing plate

-

Technical advantages:

1. Small size.

2. Super lateral force resistance, which can fasten the crane rails with super heavy load (more than 100 tons) and continuous operation.

3. Patented function of active contact between pressing plate and rail, reducing installation time.

4. Adjustable, with great security.GANTREX-W10T

GANTREX-W15T

GANTREX-W20T

GANTREX-W25T

GANTREX-W30T

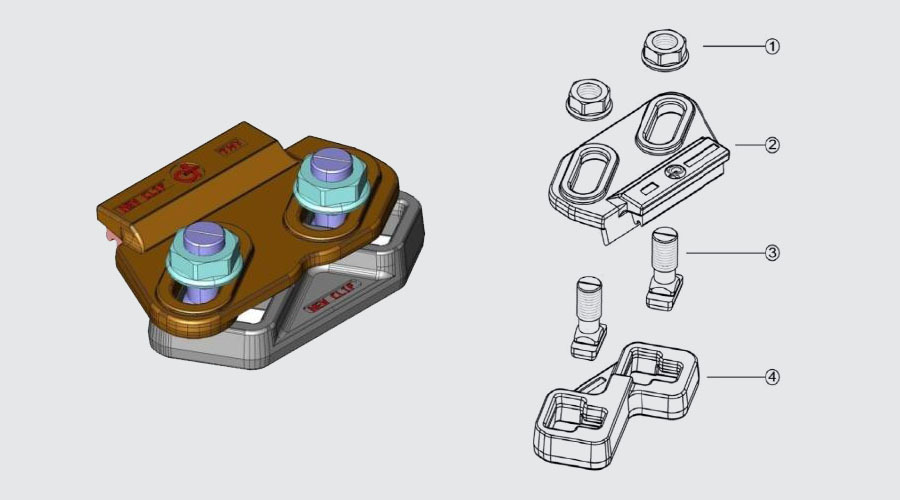

2、 RailLok ™ The bolt type pressing plate is composed of two interacting elements, which can facilitate the lateral adjustment of the track. The pressing plate fixes the track together by coordinating the bolts passing through the holes on the steel beam.

-

MAIN PRODUCTS

Learn more about our products

Track pressing plate

RailLok ™ There are two types of pressing plates: welding type and bolt type, which can be used for different fixing methods. The product has obtained an invention patent(US8205803B2, EP2173947B1, CN101720371B). Its mechanical performance has passed the test and certification of world-renowned laboratories and has been applied to professional track construction.

More +Track rubber pad

Gantrex patented pressing plate is used together with Gantrex rubber pad, which is the core of crane rail fixation solution, and can almost apply to rail models of various standards around the world. It can be continuously laid on the steel beam or on the steel backing plate of concrete. It has the properties of wear resistance, shear resistance, extrusion resistance, grease resistance, oxidation resistance and UV resistance. Because this technology requires that all rails must be welded into one piece, which completely eliminates the impact, vibration and noise generated when the wheel passes the rail joint, and can absorb 10% of the noise and 48% of the vibration generated when the rail is running, The failure rate of hoisting and transportation equipment running on rails will be reduced by more than 50%.

More +Adjustable base

Based on more than 20 years of experience, GANTREX creatively proposed a discontinuous adjustable base scheme, which greatly reduced the construction cost of track foundation in the early stage and the track maintenance cost in the later stage.

More +Track foundation repair

Relying on GANTREX's product and technical advantages, our company actively explored the uneven settlement of various track foundations generated after the coastal land reclamation in North China. Through the optimized combination of technology and materials, we successfully solved the problem of uneven settlement of track foundations. It provides guarantee for the safe and stable operation of crane rails, especially for the stable operation of unattended intelligent equipment.

More +